6.0. SURFACE ROUGHNESS

Surface roughness is an important parameter for sealing elements to work at desired effectiveness. Especially the lip part of the dynamic sealing elements are designed to provide sealing by sliding on an oil film thickness. This oil film thickness affects the sliding speed and life of the sealing element in a positive way. A high roughness of the sliding surface causes the exposure of the sealing element to dry friction by tearing the oil film thickness. This is an undesirable situation. Particularly the dynamic surfaces that touch the sealing element should be honned and grinded in order to obtain desired roughness value.

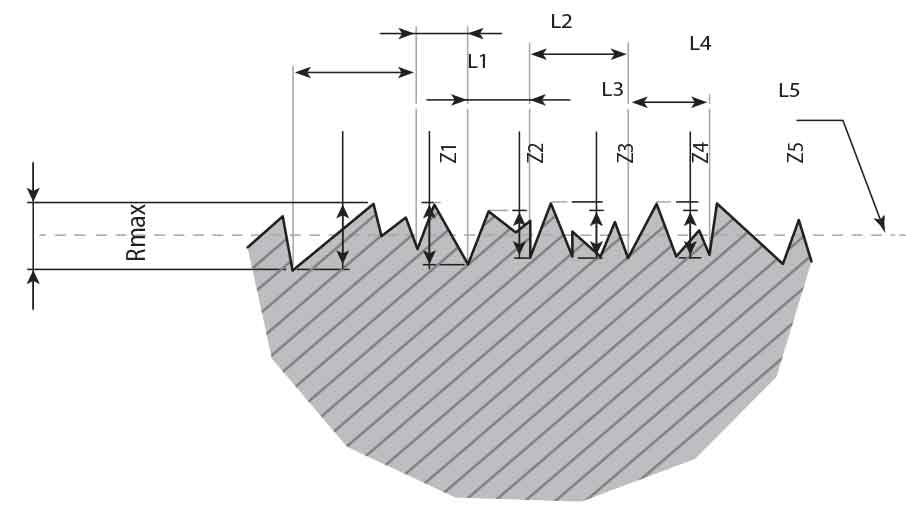

Surface roughness is measured by a device called profilemeter in terms of (μm). The measurement and calculation of the surface roughness is shown below.

Ra=Average Roughness Value

Arithmetic average of absolute values.

Rmax=Maximum Roughness Value

It is the maximum surface roughness value on the measuring line

Rz=Roughness Value of which average is taken

It shows the arithmetic mean of surface roughness depth separately (from Z1 to Z5) of five consecutive and different groups.

Rz= (Z1+Z2+Z3+Z4+Z5)/5

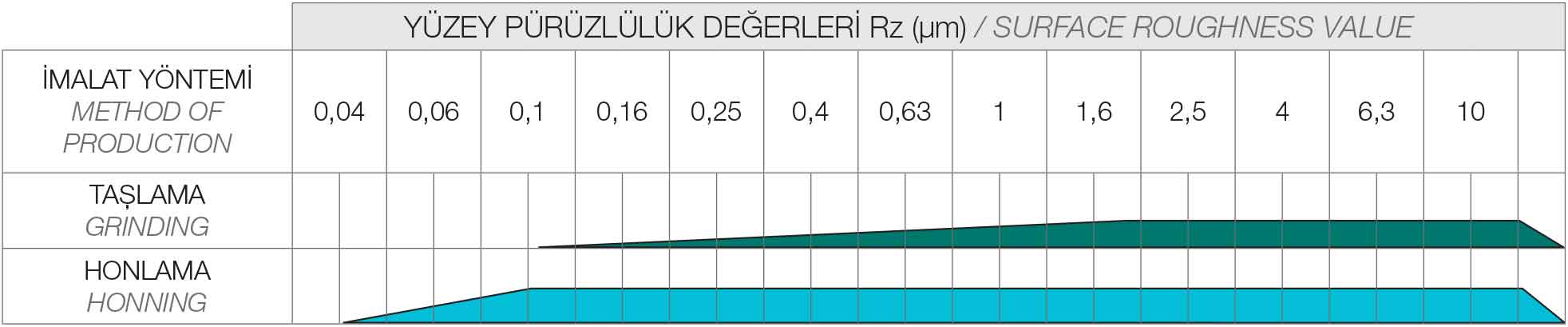

Depending on their production method, surface roughness should be between the values indicated in the table below.

Tolerance: It is the difference between the highest and the lowest measures that can be allowed. One of the important factors that affect the working of the sealing element at desired effectiveness is the tolerances of the seal housing, rod and tube. Unsuitable tolerances may cause serious problems in the system as well as affect the life cycle of the sealing element.

ISO tolerance system is used in hydraulic and pneumatic cylinders.